In the boiler, the feed water and steam flows through the different parts where the pressure is much higher than the atmospheric pressure. These parts are generally known as Boiler Pressure Parts. Mainly the heat addition to the working fluid (Water) is done through these pressure parts.

Following are the boiler pressure parts:

- Boiler Drum and internals

- Super heaters

- Re-heater

- Economizer

- Water Walls

- Air Pre Heater

Basic Flowchart

Feed Water from Economizer → Boiler Drum → Low Temperature Super heater → Radiant Super heater →Final Super heater → High pressure Turbine →Re-heater → Intermediate Pressure Turbine →Low Pressure Turbine → Steam condenses in Condenser

Super Heaters

Super-heater is mainly used to raise the temperature of saturated steam above the saturation temperature by absorbing the heat from the flue gas. Super-heater tubes are the crucial accessories which is important to improve thermal efficiency of the system. Super heater material should be capable to withstand to high temp and corrosion.Thermodynamically there is no limit on maximum temperature for superheating. Thus the maximum temperature depends on the metallurgy of the tubes.

Types of Super heater

On the basis of mode of heat transfer:

- Radiant Super heater

- Convective Super heater

On the basis of type of heat transfer:

- Parallel flow Super Heater

- Counter flow Super heater

On the basis of position:

- Platen or pendant or vertical super heaters

- Horizontal super heaters

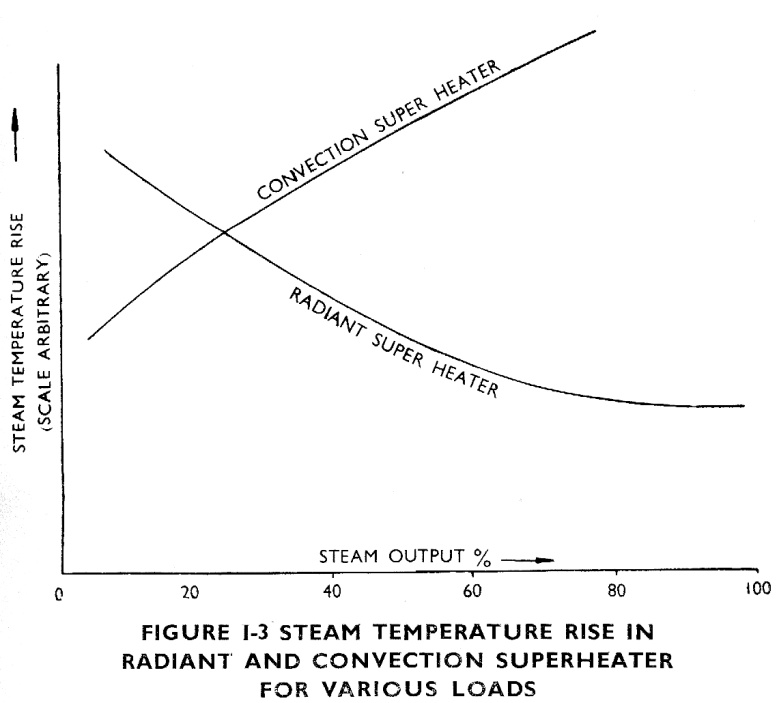

Radiant Super heater: they are exposed to heat source because of that it requires the improvement of metal temperatures. Basically we all know that

Radiant heat transfer rate = hA (Tf4-Tw4)

H : Radiant Heat Transfer Coefficient

A : Surface Area

Tf : Flame Temperature

Tw : Tube Wall Temperature

Convection Super Heater – It is located behind the banks of water tubes to avoid direct exposure to direct flame or fireball.Parameters to increase the convection heat Transfer in Boiler;

- By increasing the air fuel ratio

- By increasing the mass flow rate of steam

Re-heaters

Now a days we are dealing with larger capacity steam turbines with more stages, which posed problems of retaining the steam within vapor phase till the last stage and to overcome this problem it is very necessary to raise the temperature, after a part of the energy is extracted from the steam in the turbine. This is called re-heating of steam, which increases the cycle efficiency and we are able to maintain the dry steam in the cylinders as in case of IP and LP cylinders.

Economizer

Economizer is a heat exchange; mainly counter flow type, which is used to raise the temperature of feed water entering the boiler through the heat content available in the flue gases in the second pass of the boiler which have enough heat to transfer. The heat extracted from the flue gases is added either as sensible heat alone or sensible heat and latent heat combined to the feed water before it enters the boiler drum.

In Economizer, the re-circulation line is provided to protect the economizer tubes during boiler light up when no flow is inside the tubes.

Types of Economizer:

- Steaming Economizer

- Non Steaming Economizer

Air Pre-heaters – This is the heater which is used to heat the air before entering into the furnace. Fuel saving is directly proportional to the air temp rise in the pre heater. Every 20®c Temp drop in exit flue gas temp will increase the boiler efficiency by about 1 %.

Type of Air Pre-heaters

- Regenerative Air Pre Heater

- Recuperative Air Pre Heater

Recuperative air pre-heaters:

Here Heat is transferred directly from the hot flue gases to the air by the help of a tube type heat exchanger. They are generally in shell and tube form, where the hot flue gases flow inside the tubes and the forced air is passed around the tubes for the heat transfer.

Regenerative air pre heaters:

This is a rotating type heat exchanger, where heat is transferred in one side from hot flue gases to the heating element then to the secondary air on the other side. The most common type of rotary air pre-heater is The Ljungstorm air pre-heater. For this type of heat exchanger the value of specific heat is 1.

Water Walls (Evaporator) – Water walls are tube panel through which the water for the steam generation is circulated to the drum. In water walls, heat is added to evaporate the feed water to steam. Water walls cover all four sides as well as roof and floor of the furnace. Right and left panels extend vertically. Front and rear sloped towards inside at bottom. This reduces losses due to radiation through bottom. The rear walls are bent at the top forming a goose neck. This provides an easy flow path for the flue gases.

Materials used for Pressure parts

Radiant Super heater – SA-213 T22, SA-213 T9, SA-213 T91, SA-213 TP304H (Chrome Moly Type, Austenitic Stainless)

Low Temperature Reheater – SA-213 T12, SA-213 T11 ( Carbon Moly Type Alloy, Crome Moly type Alloy)

Water Wall – SA-178 A, SA-178 C, SA-192, SA-210A1, SA- 210C (Low Carbon, Medium Carbon)

This website is really interesting. I have bookmarked it.

Do you allow guest post on your website ?

I can provide hi quality posts for you. Let me know.

Yes we do welcome such things.So drop a mail in our inbox and we will definately consider it.